News

We would attend this Exhibition in Shanghai: RubberTech China 2023

New International Expo Center, September 04-06, 2023 Our Booth No.: 1B773

Please contact with my colleagues for any inquires:

Mr. Liming Ge +86 13352260048 (WA/Wechat)

Mr. Xiaofeng Liu +86 13352267538 (WA/Wechat)

Mr. Yufeng Ge +86-13352267498 (WA/Wechat)

Miss. Carrie +86-13352260739 (WA/Wechat)

Miss. Candice +86 13352263208 (WA/Wechat)

Mr. Jay +86 13352263296 (WA/Wechat)

Miss. Lynn +86 13029400136 (WA/Wechat)

Miss. Amy +86 13352263029 (WA/Wechat)

If so, pls feel free to inform us when would you come, I would save our time for you.

Dalian FTZ Richon Intl Trade Co., Ltd. (Sister company of Dalian Richon Chem., Ltd.)

As one of the leader suppliers for rubber chemicals, we:

Produce rubber accelerators since 1990

Produce rubber antioxidant since 1995

Main product's throughput as follow:

Accelerator MBT: 14,000mt/year

Accelerator MBTS: 5,000mt/year

Accelerator CBS: 11,000mt/year

Accelerator DCBS: 2,000mt/year

Accelerator TMTD: 4,000mt/year

Accelerator NOBS: 5,000mt/year

Accelerator TBBS: 12,000mt/year

Accelerator ZMBT: 2,000mt/year

Vulcanizing Agent DTDM: 3,000mt/year

Antioxidant TMQ: 10,000mt/year

Adhesive RA-65 (HMMM): 2,000mt/year

Antioxidant 6PPD: 40,000 mt/year

SILICA/ SILICON DIOXIDE: 150,000mt/year

RICHON brand have registered at Russia, EU, and China.

Our synthetic rubber relevant products as follows:

CR DCR SBR BR NBR IR CMS-40 SBS SEBS SIS EPDM Silicone Rubber, etc.

Welcome customers and friends to visit us and let's go forward hand in hand to create splendid victory.

Tel: +86-411-82507336 82507337 82507338

Add: I/10F Chinabank Plaza,15 Renmin Road, Dalian,116001 China

E-mail: info@richon-chem.com Website: www.richon-chem.com

In the rubber products and tire industry, tackifying resins provide the necessary viscosity during the processing process, so rubber products and tire companies are more concerned about the performance of rubber products themselves. However, the study of its viscosification mechanism should also be paid enough attention.

The theoretical research of Dalian Richon Chem on tackifying resins focuses on industries that use a large number of it, such as pressure sensitive adhesives, hot melt adhesives, etc., in these fields, the amount of it can be as high as 50 to 70 parts. Since hot melt adhesives and pressure sensitive adhesives are also composed of rubber and tackifying resins, the tackifying mechanism in these areas can also be applied to the rubber industry. The explanation mechanism can be divided into two aspects: on the one hand, the molecular adsorption and diffusion theory of rubber contact surface, and on the other hand, the formation theory of contact interface. The molecular adsorption and diffusion theory of rubber contact surface includes contact, adsorption, diffusion and other explanations, and finally unified as two-way adsorption and diffusion.

When two materials come into contact, the atoms and molecules in the material will interact with each other. These forces include strong forces such as chemical bonds, as well as weak forces such as hydrogen bonds and dispersion forces. In the case of materials, their viscosity is affected by dispersion, polarity and hydrogen bonding. In the case of rubber materials, polymers can be diffused and entangled upon contact, and through the diffusion of polymer molecules, the two surfaces are finally joined together. This is a good explanation for why small pieces of rubber become whole after a certain amount of time, because over time, the diffusion of the polymer continues and eventually forms a whole. The diffusion and entanglement of polymers are closely related to their relative molecular mass. If the relative molecular mass is small, the diffusion is easy, but the entanglement is low. If the molecular weight is high, the diffusion is difficult, but the entanglement occurs and the strength after entanglement is better. For areas that use less viscosifying resins, when considering the choice of viscosifying resins, it is also necessary to consider the effect of the relative molecular mass of the rubber used on the viscosity.

Dalian Richon is a professional rubber accelerators & antioxidants manufacturer and supplier in China. We can offer tackifying resin with high quality and moderate price. If you have any demand of rubber additives,please feel freely contact us.

According to the different functions and uses of carbon black, it can be roughly classified into: tire and rubber application carbon black, pigment carbon black and conductive carbon black. a.Carbon black for tire and rubber: The main use of carbon black is as a reinforcing agent of rubber, it can form a stable chemical bond with rubber molecular chain, so as to achieve the reinforcing effect. Generally, because the larger the surface area and the higher the structure of the carbon black, the more contact area with the rubber, the better the reinforcement will be. This type of carbon black is often used in tire tread to increase its wear resistance. For rubber products, the most important is the processing performance, usually the use of low specific surface area, high structure of carbon black, so that the rubber material is easy to process and has good extrusion characteristics, while maintaining a certain degree of physical reinforcement characteristics. About 70% of the world’s carbon black is used to make tires, which is the largest application of carbon black. About 20% of the carbon black is used for industrial rubber products other than tires, of which half are used for automotive components, so about 80% of the carbon black is consumed in the automotive industry, it can be seen that the carbon black industry is closely related to the tire industry and the automotive industry.

According to the different functions and uses of carbon black, it can be roughly classified into: tire and rubber application carbon black, pigment carbon black and conductive carbon black. a.Carbon black for tire and rubber: The main use of carbon black is as a reinforcing agent of rubber, it can form a stable chemical bond with rubber molecular chain, so as to achieve the reinforcing effect. Generally, because the larger the surface area and the higher the structure of the carbon black, the more contact area with the rubber, the better the reinforcement will be. This type of carbon black is often used in tire tread to increase its wear resistance. For rubber products, the most important is the processing performance, usually the use of low specific surface area, high structure of carbon black, so that the rubber material is easy to process and has good extrusion characteristics, while maintaining a certain degree of physical reinforcement characteristics. About 70% of the world’s carbon black is used to make tires, which is the largest application of carbon black. About 20% of the carbon black is used for industrial rubber products other than tires, of which half are used for automotive components, so about 80% of the carbon black is consumed in the automotive industry, it can be seen that the carbon black industry is closely related to the tire industry and the automotive industry.

Carbon is one of the most common elements in nature, whether it is carbon itself or the compounds composed of carbon, it has a very wide range of applications. Among all kinds of carbon materials, carbon black is one of the earliest nanomaterials used by humans. It is widely used in the rubber industry, and also contributes to the application of carbon black in plastics, ink coatings and electrical conductivity

Dalian Richon chem Co., Ltd. have begun exported Carbon black since 2003, include Thailand, Maylasia, Mexico, Turkey and Egypt.

Carbon black is composed of more than 95% carbon, as well as a small amount of oxygen, sulfur, nitrogen and ash, is a kind of soot, texture is extremely light and fine black powder, so it is also known as carbon smoke. The particle size of primary carbon black particles is about 10-500nm, which is stacked by layers of molecular structures similar to stone grinding. If observed by electron microscope, it can be found that carbon black does not exist as a single particle, but is closely connected by one primary carbon black particle to form a grape string aggregate. This is the primary structure of carbon black; The primary structure will be adsorbed to each other into agglomerate due to the Van der Waals force, and finally after granulation, it is the carbon black particles visible on the market.

Method of making carbon black: Carbon black is a product obtained by pyrolysis or incomplete combustion of carbonaceous hydrogen compound as raw material. At present, the most important production method of Richon Chem is the oil furnace method of carbon black, using heavy petroleum oil such as tower bottom oil and creosote as raw materials, introducing the high temperature of 1800℃ reactor, accurately controlling the reaction parameters, producing carbon black with multiple applications and high thermal tail gas, and the tail gas can further produce steam and electricity.

Characteristics of carbon black: Since the primary particles of carbon black are stacked by many graphite-like molecules, such a multi-pore structure makes carbon black have certain surface physical and chemical properties, and makes carbon black have excellent reinforcement, coloring power and electrical conductivity, which are affected by the primary particle size, structural complexity and functional groups on the surface of carbon black particles.

Dalian Richon is a professional rubber accelerators & antioxidants manufacturer and supplier in China. We are the manufacture of carbon black. The product of high quality and low price. Our products have been exported to 76 countries. If you would like to know more about it, please click on the website and contact us.

Website: https://www.richon-chem.com/

E-mail: info@richon-chem.com

We would attend this Thailand Exhibition:

Global Rubber, Latex & Tyre Expo 2023

BITEC Bangkok, Mar.29-Mar.31, 2023

Our Booth No.: H17

Please contact with my colleague for any inquires:

Mr. Yufeng Ge +86-13352267498 (WA/Wechat)

Miss Shirley +86-13352267458 (WA/Wechat)

Miss Carrie +86-13352260739 (WA/Wechat)

If so, pls feel free to inform us when would you come, I would save our time for you.

DALIAN RICHON CHEM CO.LTD

As one of the leader suppliers for rubber chemicals, we:

Produce rubber accelerators since 1990

Produce rubber antioxidant since 1995

Main product's throughput as follow:

Accelerator MBT: 14,000mt/year

Accelerator MBTS: 5,000mt/year

Accelerator CBS: 11,000mt/year

Accelerator DCBS: 2,000mt/year

Accelerator TMTD: 4,000mt/year

Accelerator NOBS: 5,000mt/year

Accelerator TBBS: 12,000mt/year

Accelerator ZMBT: 2,000mt/year

Vulcanizing Agent DTDM: 3,000mt/year

Antioxidant TMQ: 10,000mt/year

Adhesive RA-65 (HMMM): 2,000mt/year

Antioxidant 6PPD: 40,000 mt/year

SILICA/ SILICON DIOXIDE: 150,000mt/year

RICHON brand have registered at Russia, EU, and China.

Our sister company Dalian FTZ Richon Intl Trade Co., Ltd. also export synthetic rubber, include:

CR DCR SBR BR NBR IR CMS-40 SBS SEBS SIS EPDM Silicone Rubber

Welcome customers and friends to visit us and let's go forward hand in hand to create splendid victory.

Tel: +86-411-82507336 82507337 82507338

Add: I/10F Chinabank Plaza,15 Renmin Road, Dalian,116001 China

E-mail: info@richon-chem.com Website: www.richon-chem.com

Power Rationing, Raw Material Prices Increased

In last few months, Dalain Richon Chem Co., Ltd. feels very difficult to supply enough products to our customers.

Power supply constraints plus double control of energy consumption, power rationing, production suspension are effecting many provinces in China

Recently, many places have issued new government policy documents of "DUAL CONTROL OF ENERGY CONSUMPTION", and all kinds of industries with high energy consumption and high pollution have stopped production. Power rationing and shutdowns are affecting at least 10 provinces, including Jiangsu, Zhejiang, Shandong, Guangxi, Liaoning and Yunnan

The impact of energy consumption control policy on upstream enterprises is bigger, and the price of raw materials rises sharply again, leading to more difficult business for rubber chemical manufacturers.

Yesterday, one of our plant has received a verbal notice of "work 4 stop 3", not to shut down from Friday to Sunday, but there are still three hours of blackout every day.

Power rationing will lead to an increase in production costs, and more seriously the productivity will be slashed, and the delivery cycle will be extended. Plus the holiday peak season around the world is coming soon, and all customers are pressing for delivery.

Dalian Richon’s sales increased 80% in first 9 months of 2021.

Now we have to be more cautious to accept new orders. We need to explain to customers in advance that the delivery period will be extended by at least 1 to 2 weeks. The impact is hard to estimate, and it is not clear how long the power rationing will last.

Anyway, Dalian Richon still keep all contracts with our customers and will try our best to serve our partners during this hard time.

Characteristics of guanidine accelerators:

Dalian Richon Chem note guanidine accelerators most used alkaline accelerators, which is a medium-speed accelerator for natural rubber and synthetic rubber. The vulcanization starts slowly, the operation safety is good, and the vulcanization speed is also slow. The biggest feature is the high degree of vulcanization, resulting in high hardness and high constant elongation stress.

The promotion effect lasts for a long time, which can make the rubber material vulcanize for a long time. It is suitable for the vulcanization of thick products (such as rubber rollers), but the product is easy to age and crack, and has discoloration and pollution, which is not suitable for white products. .

Due to the slow vulcanization speed and poor heat aging resistance, guanidine accelerators are generally not used alone, but as the second accelerator for thiazoles and sulfenamides. When used together, the activation effect is particularly strong, and it can only be used alone in hard rubber products.

The main varieties of guanidine accelerators include: accelerator DPG(D), DOTG, BG, TPG, POTG 5. Among them, the guanidine compounds provided by Dalian Richon Chemical Co., Ltd. are accelerator DPG and accelerator DOTG. The details will be introduced below.

1 DPG (D)

DPG, also known as 1,3-Diphenylguanidine, is a white powder, non-toxic, with a critical temperature of 141°C, soluble in chloroform, toluene, benzene and ethanol; insoluble in gasoline and water. Does not absorb moisture.

The scorch time is longer, the vulcanization speed is slow, the flatness is poor, the vulcanizate has high tensile strength, constant elongation stress, high hardness, poor heat aging resistance, discoloration and pollution.

Dosage: 1~2 parts as the first accelerator, 0.1~0.5 parts as the second accelerator.

2 DOTG

DOTG, also known as 1,3-di-O-tolylguanidine, is a white powder with similar performance to DPG, safer operation, and higher cross-linking degree than DPG.

Dosage: 0.8~1.5 parts as the first accelerator, 0.1~0.5 parts as the second accelerator.

2.The application of guanidine accelerators

Guanidine accelerators are generally not used independently, but as the second accelerator of thiazoles and sulfenfluorobenzenes. It is used in the production of rubber sheets, shoe soles, bicycle tires, industrial products and their thick products, and hard rubber products.

1 Accelerator DPG

Used as a medium-speed accelerator for natural rubber and synthetic rubber, mainly used in the manufacture of tires, rubber sheets, rubber shoes and other rubber industrial products.

Used as an auxiliary accelerator for thiazole and sulfenamide in NR and SBR compounds. Compared with thiuram and dithiocarbamate, it shows better storage stability, but is not as active. DPG can be used as an auxiliary gelling agent (foam stabilizer) in the fluorinated silicon foam process in latex.

2 Accelerator DOTG

It can be used for natural rubber and diene synthetic rubber. Applicable to NR, SNR, IIR, IR, SBR, NBR and CR. Rarely used alone, usually used together with thiazoles, thiurams, dithioamino horses and sulfenimides to improve its activity. This product is a CR plastic decomposer. However, this product is not suitable for food-related products or medical products.

Author: LN – Dalian Richon Chem Co., Ltd.

Dated: 2021-09-06

Dalian Richon glad to introduce Dithiocarbamate accelerators are ultra-overspeed accelerators. It has low active temperature, fast vulcanation speed, and high crosslinking degree. Suitable for thin products, room temperature sulfide products, rubber dairy products, butyl rubber and sulfurized products of EPDM rubber.

Among them, ammonium dithiamate, sodium, potassium as water-soluble accelerators, mostly used as sulfide accelerators for glue dairy products; zinc dithiamdine promotion activity is lower than ammonium salt, has certain operating safety in dry glue, thiazole, autumn um, potassium promoters in thithiamate, sodium, and latex, which is also the most commonly used varieties.

Dalian Richon can provide dithiocarbamate accelerators include: ZDMC(PZ), ZDBC(BZ), ZDEC(ZDC,EZ), ZEPC(PX), ZBEC(DBZ), TDEC, CDMC(CDD). The following is a detailed introduction to the product we can provide.

1.ZDMC(PZ)

ZDMC chemical name is zinc dimethyl dithiocarbamate, white or light yellow powder, specific gravity is 1.66, slightly soluble in ethanol and carbon tetracloride at 25℃. It easy to disperse in rubber, suitable for light and bright color products, mainly used for latex products, can also be used for self-sulfur glue, adhesive, cold sulfur products, food rubber products.

2.ZDBC(BZ)

ZDBC chemical name is dibutyl dithiocarbamate zinc, white powder, soluble in carbon disulfide, benzene, chloroform, ethanol, ether, insoluble in water and dilute alkali, stable storage. It is a super accelerator for natural rubber, synthetic rubber and latex, the latex which containing ZDBC can be used for a week without early vulcanization phenomenon. It has the function of antiaging agent in the mixing rubber, can improve the aging resistance of vulcanized rubber, no color, no pollution, and easy to disperse. It is often used for low temperature vulcanized mortar, vulcanizing faster than EZ and PZ.

ZDEC chemical name is zinc diethyl dithiocarbamate, white powder, soluble in 1% NaOH solution, carbon disulfide, benzene, chloroform, insoluble in gasoline. ZDEC is used as a superaccelerator for NR, synthetic rubber and latex, especially for butyl rubber, EPDM and latex, non-toxic, inodorous, it can be used as white or brilliant color and transparent rubber manufactures.

4.ZEPC(PX)

ZEPC chemical name is zinc ethyl phenl dithiocarbamate, white powder, odorless and non-toxic, soluble in hot chloroform, hot benzene, slightly soluble in gasoline, benzene, toluene, hot alcohol, insoluble in acetone, carbon tetracloride, ethanol and water. It is a super accelerator which is safer to operate, especially suitable for latex vulcanization. It can be used to make impregnated latex products in contact with food and transparent and brilliant products, medical supplies, latex model products, impregnated products, latex sponge, tape, self-sulfur glue and so on. It can also be used as activator of thiazole accelerators.

ZBEC chemical name is zinc dibenzyl dithiocarbamate, white powder, soluble in ethanol, benzene and chloroform, insoluble in water. ZBEC is a new type of environmental protection secondary thiocarbamate vulcanization accelerator. It does not produce carcinogenic nitrosamine in the use process, the vulcanization activity temperature is low, the operation is safer, has the longest anti-coke performance, can be used to replace PZ, EZ, ZDBC, TMTM, etc.

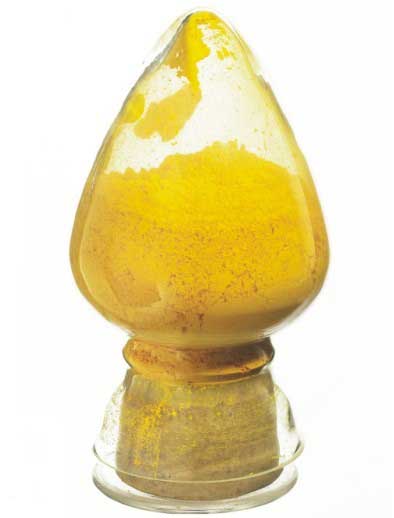

6.TDEC

TDEC chemical name is diethyl thio-carbamate tellurium, yellow powder, relative density of 1.48, soluble in chloroform, benzene and carbon disulfide, slightly soluble in alcohol and gasoline, insoluble in water. It is used as a natural rubber and synthetic rubber overspeed vulcanization accelerator, generally with thiazole, secondary sulfonamide accelerator, mainly used in the manufacture of inner tube, cable insulation layer, hose, etc.

7.CDMC(CDD)

CDMC chemical name is dimethyldithiocarbamate, it has a slight rubber staining property and is suitable for NR, SBR, NBR, IIR and EPDM systems, especially for SBR, IIR and EPDM systems. The efficiency of promoting vulcanization is better than TT, PX, etc.

Author: WYY – Dalian Richon Chem Co., Ltd.

Dated: 2021-08-26

Richon glad to introduce thiuram accelerators are a very important class of accelerators. It includes thiuram monosulfide, thiuram disulfide and thiuram polysulfide. Among them, thiuram disulfide and thiuram polysulfide can release active sulfur or sulfur-containing free radicals at standard vulcanization temperatures, so they can be used as vulcanizing agents.

The thiuram accelerator has a thiuram derivative with the general structural formula (R, R'are alkyl, aryl, cycloalkyl, etc.; x = 1 to 6). Including thiuram monosulfide, thiuram disulfide and thiuram polysulfide. It is an acidic super accelerator with activity between dithiocarbamate and thiazole accelerators. It is generally used as a second accelerator to increase the vulcanization speed and vulcanization degree of thiazole and sulfenamide accelerators. . Disulfide and polysulfide thiuram can release active sulfur at standard vulcanization temperatures, and can be used as a sulfur donor in sulfur-free vulcanization systems.

Representative varieties are tetramethylthiuram monosulfide (TMTM), tetramethylthiuram disulfide (TMTD), tetraethylthiuram disulfide (TETD), tetramethylthiuram disulfide ( DPTT) and so on.

Dalian Richon Chemical Co., Ltd. can provide you with TMTD (TT), TETD, TMTM, TRA (DPTT), TiBTD, TBzTD, TBTD, these thiuram accelerators.

TMTD is a general-purpose accelerator for natural rubber and synthetic rubber. It is also widely used as a fungicide and seed soaking agent in agriculture. Rubber accelerator TMTD is an excellent second accelerator for thiazole accelerators. It can also be used with other accelerators as an accelerator for continuous vulcanization of rubber particles. Usually it can also be used with accelerator MBT (M). In this case, it can be used with butyl rubber. The vulcanization is basically similar. The accelerator is mainly used in the manufacture of tires, inner tubes, rubber shoes, medical supplies, cables, industrial rubber products, etc. It is used as a fungicide and insecticide in agriculture, and can also be used as a lubricant additive.

2. TMTM (TS)

TMTM is a green and environmentally friendly rubber vulcanization accelerator. It can be used not only as a vulcanizing agent, but also as an effective activator for thiazole and sulfenamide accelerators. It has the function of a secondary accelerator and makes the dispersion of thiazole and sulfenamide more good, and the product is transparent. . It is widely used in natural rubber, diene synthetic rubber, isobutyl rubber, ternary isopropyl rubber, W-type chloroprene rubber. It can be used to prepare wires, cables, rubber boots, Toys, transparent products, waterproof cloth, medical rubber products, gloves, etc.

3. DPTT(TRA)

DPTT is a white or gray-yellow powder. It is soluble in carbon disulfide, chloroform and carbon tetrachloride, but insoluble in water. It can be used for natural rubber, diene synthetic rubber, butyl rubber, EPDM rubber, chlorosulfonated polyethylene and latex. Free sulfur can be decomposed by heating, and it can also be used as a vulcanizing agent. The effective sulfur content is 25% of its weight. When used as a vulcanizing agent, this product is relatively safe at operating temperature, and the vulcanized rubber has excellent heat resistance and aging resistance. This product is easy to disperse in dry rubber and water. No pollution. Generally used in the manufacture of heat-resistant products, cables, etc.

4. TBzTD

The rubber accelerator TBzTD is to replace TMTD, mainly because thiuram accelerators are prone to produce carcinogenic nitrosamines, while diphenylnitrosamines are not carcinogenic. It is used as an accelerator or secondary accelerator for NR, SBR, EPDM, NBR systems. It is safer and has a longer anti-scorch time than TMTD. It is sometimes used as a PVC rubber vulcanization inhibitor.

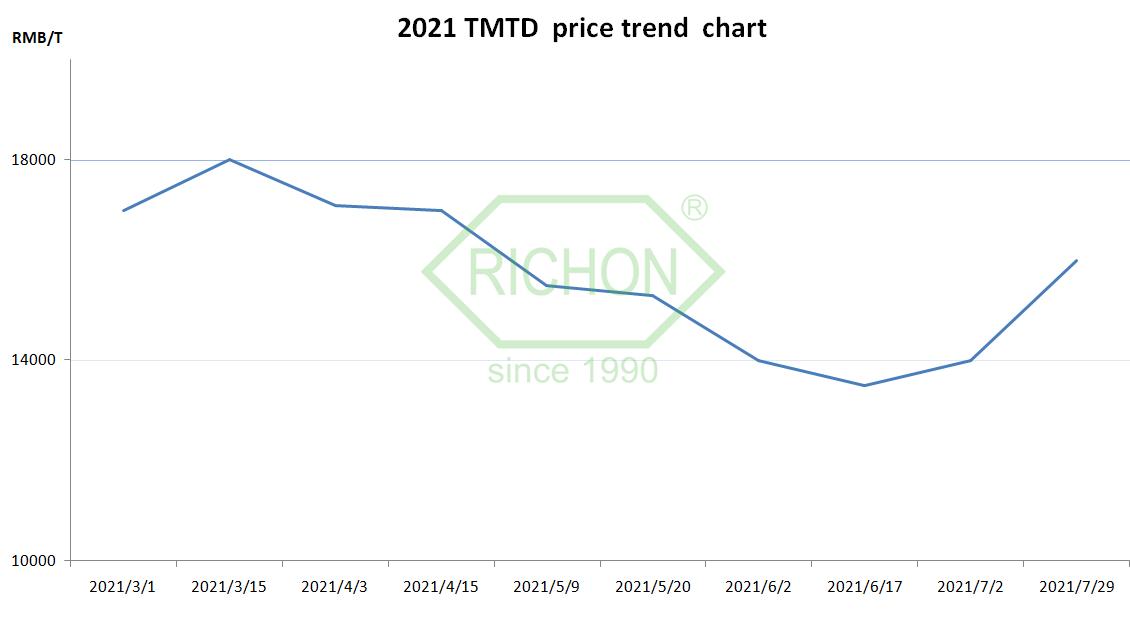

DalianRichon Chemical Co., Ltd. provides a domestic 2021 TMTD price trend chart.

Dalian Richon note recently TMTD’s price increased very sharply because raw materials’ price up so much.

Author: MYJ – Dalian Richon Chem Co., Ltd.

Dated: 2021-08-26

Sulphonamide Rubber Accelerators

Richon note new type promoters for tire Tire compound usually uses secondary sulphonamide promoters as main promoters, and guanidine or Thiuram as auxiliary promoters, which can make the vulcanized rubber get good mechanical properties and make the tire get good performance.

1.Introduction

This is a late acting accelerator, which is acidic. It has the characteristics of long coking time and great vulcanization activity. Degree of vulcanization of a vulcanized adhesive

Relatively high, excellent physical and mechanical properties, aging resistance is quite good. The compound has a wide vulcanization flatness. Due to the development and extensive application of synthetic rubber and the promotion and application of high dispersion furnace carbon black, special demand for good delay of the accelerator.

Therefore, this kind of accelerator occupies a very important position, and has become the fastest developing and the most promising type of accelerator in recent years.

2.Feature

1) it has tardive, long burning time, fast vulcanization speed, flat vulcanization curve, and good comprehensive properties of vulcanized rubber.

2) it should be cooperated with furnace carbon black, which has full security and is conducive to the full fluidity of pressing, calendering and molding rubber.

3) Suitable for high temperature rapid vulcanization of synthetic rubber and vulcanization of thick products.

4) With acid accelerator (TT), the formation of activated sub sulphonamide sulfide system, can reduce the amount of accelerator.

5) In general, the induction period of sulphonamide promoters is related to the size and quantity of the groups connected with the amine group.

3.Category

Among the various accelerators used in the world at present, Sulphonamides are the main ones, among which CBS(CZ), NOBS(MBS/MOR), TBBS(NS), DCBS(DZ), CBBS, TBSI and OTOS are widely used, most of which are derivatives of mercaptan benzothiazole. Among them, Dalian Richon can provide the following products:

CBS(CZ), NOBS(MBS/MOR), TBBS(NS),DCBS(DZ),CBBS,TBSI.

4.Product introduction

1)CBS(CZ):

Properties: A slight odor. Soluble in benzene, chloroform, carbon disulfide; Insoluble in water.

Application: A medium fast primary accelerator suitable for NR, IR, SBR, NBR, HR and EPDM. An outstanding delayed action accelerator. Be top effective and safe when used at ordinary processing temperatures, causing no scorches. Vulcanized show excellent physical property and quick complete. Usually used alone, when activated by D, TT and TS.

Appearance:Grayish-white powder/oiled powder/ granular.

Picture: granular for reference.

Properties: Light yellow or orange granular. No poison with a little odor of ammonia. Soluble in benzene, acetone. chloroform, insoluble in water and acid, alkali with lower concentration.

Application: An excellent delayed accelerator. The performance is similar as CZ with better scorch safety Widely used in NR, IR, SBR, NBR and EPDM. Can be used alone or with other vulcanization accelerators such as thiurams, guanidines and dithiocarbamates to improve the activity. Mainly used in manufacture of tires, shoes and belts.

Appearance:Light yellow or orange granular.

Picture: granular for reference.

3) TBBS(NS)

Properties: Without foul odor, but with bitter taste, easily soluble in benzene, carbon tetrachloride.

ethylene chloride; soluble in gasoline, ethylacetate, ethanol, acetone; insoluble in water.

Application: The product posses the best scorching quality of sulphonamides type accelerators. Its scorching quality in natural rubber is better than DIBS, the operating safety is much better. Mainly used in manufacturing of tires, rubber belts and shock absorber.

Appearance:Light yellow powder/ oiled powder/granular.

Picture: powder for reference.

4) DCBS(DZ)

Properties: Light yellow or light pink powder (granular) with taste bitter. Soluble Acetone Organic liquids, including fats and oils, insoluble in water.

Application: DCBS is a sulphonamide accelerator with excellent anti-scorching property and delayed onset of cure. It is compatible with natural and synthetic rubbers, suitable for radial ply tire, rubber belts and shock absorber, etc. Particularly it produces good adhesion to metal.

Appearance:Light yellow or light pink powder/oiled powder/granular

Picture: granular for reference

5) CBBS

Properties: Gray to white powder.

Application: CBBS is nitrosamines free products in application, showing longer scorch safety, better anti-reversion curing, lower curing speed, higher modulus and lower HBU of NR and diene rubbers than the standard CBS. To replace DCBS for the tire steel cord bonding compounds show excellent heat resistance and service durability. Suitable for tires, belts, hoses, and other TRG articles.

Appearance: Gray to white powder

Picture: powder for reference

6) TBSI

Properties: Off-white crystalline powder. Soluble in alcohol, partly soluble in diethyl ether, insoluble in water.

Application: TBSI can obtain good scorch safety and lower vulcanization rate, and show good curing reversion resistance. It can also replace primary amine accelerator TBBS and scorching retarder CTP blend and be used alone. It can improve adhesive performance between rubber and steel cord, and also improve storage stability of rubber compounds; it can replace NOBS which is carcinogenic. It can be applied to all the diene rubbers, especially thick section rubber products with high requirements on reversion resistance.

Appearance:Off-white crystalline powder

Picture: powder for reference

7) OTOS

Properties: White to gray powder, partly soluble in water.

Application: OTOS is a fast curing accelerator for natural and synthetic rubber. Especially suitable for tire, rubber shoes, hose etc. It’s non-staining but will cause slight discoloration in white or light colored compounds.

Appearance:White to gray powder

Picture: powder for reference

Author: MYJ – Dalian Richon Chem Co., Ltd.

Dated: 2021-07-26